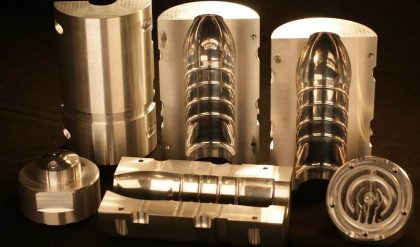

Below are the most common injection mould tool types we can offer you, together a definition of what the tool can achieve & the projects it is suitable for, as well as a Cost Comparison.

We can offer you various mould tool options e.g. a family tool or separate automatic unscrewing tools, thus you can choose the type to match your project needs.

| Tool Type | Definition | Suitability / Comments |

| Core Pulling (Manual) | Makes parts with side holes & features, but needs machine operator to manually remove tool parts to get finished part | Low – medium quantities of more complex parts. Lower tool cost than automatic cp tool, higher moulding costs |

| Core Pulling (Automatic) | Contains mechanism to automatically produce holes & features in parts which otherwise could not be released from tool | Medium – high quantities of more complex parts. Higher tool cost than manual cp tool – moulding costs lower, larger amounts made quicker |

| Family | Makes several different shaped & sized parts to produce a set made in same material & colour | Low – medium quantities of kit type parts e.g. knife, fork & spoon set |

| Hot Runner | Uses heated tool parts so standard cavity feed not needed & only parts (no waste) are made | Medium – high quantities of parts needing lower costs. Higher tool cost than standard tool |

| Insert (Manual) | Makes parts with feature holes which enable metal inserts to be e.g. pushed in afterwards | Low – medium quantities. Cost benefits or losses depend on job |

| Insert (Semi-Auto) | Moulds around inserts put in tool by machine operator to make parts inc. metal inserts | Low – medium quantities. Cost benefits or losses depend on job |

| Multi Impression | Makes several identical parts | Medium – large quantities, higher tool cost than single impression, moulding costs lower, larger amounts made quicker |

| Overmould | Moulds around parts put in tool by machine operator to make final part e.g. shaver plug | Low – medium quantities of parts needing encapsulation |

| Single Impression | Makes one part only | Low quantities, tool cost lower than multi impression, higher moulding costs |

| Thread manual unscrewing | Makes parts with screw thread/s, but machine operator needed to manually unscrew tool inserts to get finished parts | Low – medium quantities of screw threaded parts. Lower tool cost than automatic unscrewing tool, higher moulding costs |

| Thread automatic unscrewing | Contains mechanism to automatically make & unscrew parts with screw threads | Medium – high quantities of screw threaded parts. Higher tool cost than manual unscrewing tool – moulding costs lower, larger amounts made quicker |

| Universal | Gate position offset or moved to enable parts to be made in e.g. small machine & split position | All moulding quantities. Part & tool costs lower than standard due to machine efficiency |

| Upgradeable | Larger than if made to make e.g. just 1 part, only 1 or more impressions produce parts, with others blank, but upgradeable in future | Good for if moulding quantities are likely to increase in the future. Higher tool cost than if tool made to make e.g. just 1 part |

Please view our help page for more injection mould tool help. Alternatively, return to the Toolmaking Page